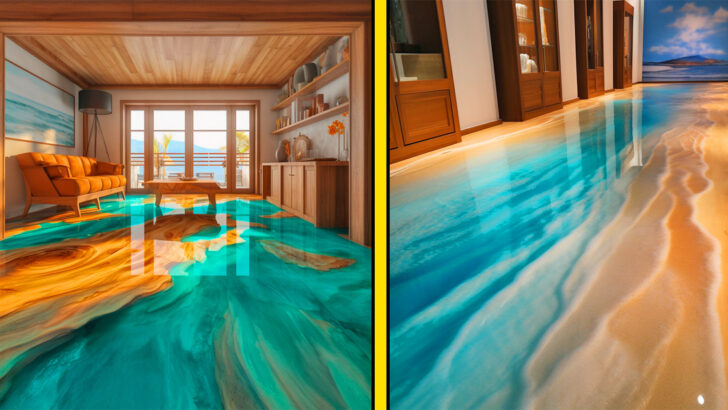

Picture the gentle lull of ocean waves, the feel of warm sand underfoot, and the pure bliss of basking in a sunny, seaside ambience. Now, imagine bringing that tranquil beach experience directly into your home. This is the innovative promise of luxury beach-themed flooring, a pioneering concept in interior design.

Designed to resemble an authentic sandy beach, this bespoke flooring style uses real sand and a protective epoxy layer to create a seamless, flat surface. The sand, sculpted to replicate the natural contours and ripples of a beach, is subsequently covered with a clear, durable epoxy. This aesthetic not only preserves the beach’s lifelike charm but also makes the floor easy to walk on.

This distinctive flooring solution best complements beach-themed or coastal style interiors. The floor serves as the focal point in such settings, evoking a coastal vibe that harmonizes with nautical decor, breezy color palettes, and natural light. Spaces adorned with driftwood accents, linen fabrics, and sea-inspired artworks could especially benefit from this beachy foundation.

Ideal for those with an adventurous spirit and a love for the ocean, this flooring is perfect for beach enthusiasts who yearn for that year-round summer feeling. Whether it’s homeowners desiring a permanent vacation atmosphere, or businesses aiming to create a unique, captivating environment, this flooring brings the beach to you.

The craftsmanship involved in creating this coastal masterpiece is truly exceptional. Crafting a single room requires intensive labor, meticulous attention to detail, and a profound understanding of materials and techniques. The floor’s design must mimic the irregularities of a natural beach, which means that every grain of sand plays a part in the final product.

The production process for a single room can take approximately 100-120 hours. This timeframe includes the stages of initial design, layout creation, sand sculpting, and epoxy application. The process concludes with a curing period to ensure the durability and longevity of the floor.

Given its exclusivity and the labor-intensive creation process, this unique flooring solution is estimated to cost between $70 and $100 per square foot. This includes the cost of materials, labor, and the customization necessary to create a bespoke beach scene for each client.

Undoubtedly, this type of flooring is a dazzling addition to any interior space, instantly catching the eye and sparking conversation. Its uniqueness lies not only in its aesthetic appeal but also in its narrative – a story of craftsmanship and passion infused into every grain of sand.

For homeowners or businesses looking to bring this exceptional aesthetic into their spaces, specialized interior design or flooring companies that work with unique materials and bespoke designs are the go-to choice. These companies would have the expertise to handle the complex processes involved in creating such a remarkable floor.

Now, let’s delve a bit into the procedure of creating this sandy beach flooring with epoxy. The process begins with a thorough inspection and preparation of the existing floor. This is followed by a precise layout of the beach design using real sand. Once the desired look is achieved, the sand is fixed in place with a binding agent.

Following this, a clear epoxy resin, known for its durability and resistance to wear and tear, is carefully poured over the sculpted sand. This creates a flat, walkable surface that also enhances the visual depth of the sand below. After the epoxy application, the floor is left to cure for several days, culminating in a sturdy, glossy surface that perfectly mimics a beach, yet is practical for everyday use.

Embodying the ultimate synthesis of luxury, creativity, and the love for the beach, this flooring is truly a masterpiece in design. Its charm and character offer an immersive beach experience, transporting you to a world of coastal serenity right within your own four walls. With beach-themed flooring, the idyllic beach escape is now, quite literally, under your feet.

While the uniqueness of the design adds unparalleled aesthetics to your home, the comfort and warmth of the sandy texture make it an experience beyond the ordinary. It is not just about walking on the beach; it’s about feeling the beach, its tranquil vibes and soothing charm within the realm of your living space.

One of the most appealing aspects of this type of flooring is its versatility. Depending on personal preferences and interior design requirements, the beach can be sculpted to resemble any coastline in the world.

From a Mediterranean beach with its fine sand to a tropical shoreline with coarser textures, there’s a world of possibilities to explore. The sand’s color, grain size, and arrangement can be tailored to mimic your favorite beachfront, making your flooring truly one-of-a-kind.

Choosing beach-themed flooring also conveys a deep appreciation for nature and its aesthetics. This choice demonstrates an individual’s desire to bring the outside in, forming an intimate connection between the home and the natural world. It’s a commitment to transform the mundane into extraordinary, making everyday life feel like a permanent holiday.

Taking care of this type of flooring is surprisingly easy. The epoxy coating creates a water-resistant barrier, protecting the sand beneath from spills and stains. Regular sweeping and occasional mopping with a damp cloth are enough to maintain the pristine appearance of your beach floor. For more extensive cleaning, a non-abrasive cleaner can be used without damaging the epoxy surface.

Despite its luxurious appeal, this flooring is surprisingly durable, capable of withstanding the usual wear and tear associated with high-traffic areas. Its resilience makes it a practical choice for both residential and commercial spaces, from living rooms and bedrooms to boutiques and coffee shops.

Furthermore, it’s a well-known fact that the sight and sound of the beach have a calming effect on the mind. Research suggests that beach-themed interiors can have similar soothing effects, making this flooring an excellent choice for stress relief. Imagine coming home after a long day of work to the visual comfort of your very own beach haven.

The creation of this luxurious flooring is an ode to craftsmanship, innovation, and the pursuit of unique interior design experiences. Its authenticity, aesthetic appeal, and comforting presence make it a spectacular addition to any home or business.

A room adorned with this beach-themed flooring is more than a space – it’s a slice of coastal paradise, a testament to the homeowner’s exquisite taste, and a constant reminder of the beautiful intricacies of nature. Indeed, with this groundbreaking flooring solution, the beach is no longer a destination, but a lifestyle.

Creating a Sandy Beach Floor with Epoxy: A Detailed Guide

To illustrate the process, let’s consider the example of a 12×12 feet (144 square feet) room.

Materials Required:

- High-quality play sand – around 20 bags of 50 pounds each (1,000 lbs total).

- Clear Epoxy Resin – depending on the thickness, you’ll need around 5-6 gallons.

- Epoxy hardener – usually sold with the resin, in the ratio as specified by the manufacturer.

- Primer/sealer for the concrete base – 1 gallon.

- Concrete binding adhesive – 1 gallon.

- Miscellaneous supplies: gloves, safety glasses, painter’s tape, trowels, mixing bucket, epoxy roller, paintbrushes, and a leveling tool.

Procedure:

- Floor Preparation: Ensure that the floor is clean, dry, and free of dust or debris. If the floor is concrete, apply a primer or sealer and let it dry.

- Sand Layout: Mark the area where you plan to create your beach scene with painter’s tape. Spread the sand across this area, shaping and sculpting it to create a beach-like texture. Remember, the natural beach isn’t perfectly flat, so vary the sand height to imitate the natural look.

- Adhesive Application: After the sand layout, apply a layer of concrete binding adhesive on the sand to fix it in place. It helps prevent the sand from shifting during the epoxy application. Allow it to dry thoroughly.

- Epoxy Mixing: Mix the epoxy resin and the hardener in a large bucket according to the manufacturer’s instructions. Make sure to stir it thoroughly until you get a clear mixture. Always wear safety gloves and glasses during this step to protect yourself from potential skin or eye irritation.

- Epoxy Application: Pour the mixed epoxy carefully over the sand. Start from one corner and move to the opposite side, ensuring the epoxy covers the sand completely. Use an epoxy roller to evenly spread the epoxy across the surface. Ensure the layer is thick enough to create a flat surface but thin enough to keep the sand texture visible.

- Leveling and Curing: Use a leveling tool to smooth the epoxy surface. Make sure the entire area is covered, and there are no air bubbles in the epoxy. Leave it to cure for several days as recommended by the epoxy manufacturer.

- Final Touches: Once the epoxy is fully cured, inspect the floor for any imperfections or missed spots. If you find any, you can spot-treat these areas with a small amount of mixed epoxy.

Time and Cost Estimation:

For a room of this size, expect the entire process to take around 40-50 hours, excluding curing time. This includes the time spent on floor preparation, sand layout, and epoxy application.

As for cost, let’s make a rough estimate:

- Sand: Around $5 per 50lb bag, so $100 for 1,000 lbs.

- Clear Epoxy Resin: Approximately $100 per gallon, so $500-$600 for 5-6 gallons.

- Primer/Sealer: Around $30 per gallon.

- Concrete Binding Adhesive: About $50 per gallon.

- Miscellaneous supplies: Approximately $100.

This brings the total material cost to around $780-$880. However, if you’re hiring professionals, the cost will increase significantly, as it involves skilled labor and detailed work. With labor costs added, the cost may reach around $70-$100 per square foot, or $10,080-$14,400 for a 144 square foot room. This is not a small investment, but the end result is a unique, eye-catching floor that adds immense aesthetic appeal to any space.

It’s also worth noting that, as with any home improvement project, these cost estimates are approximations. Prices for materials can vary depending on your location, the quality of the products you choose, and local labor rates.

If you’re considering doing this as a DIY project, keep in mind that while it may save on labor costs, creating a beach-themed epoxy floor requires a significant amount of time and effort. Plus, working with epoxy can be tricky, particularly for beginners. If not mixed and applied properly, epoxy can bubble, peel, or not set correctly, leading to unsatisfactory results.

Additionally, given the fumes produced during the mixing and application of epoxy, ensure you work in a well-ventilated area and wear appropriate protective gear, including gloves, safety glasses, and a respirator. This will protect you from potential skin, eye, and respiratory irritation.

All things considered, creating a sandy beach floor with epoxy, whether as a DIY project or by hiring professionals, is an ambitious but achievable endeavor. When done correctly, the resulting floor can transform a regular room into a unique, beach-inspired haven, making the investment of time and money well worth it for many homeowners.

Shydon

Wednesday 18th of October 2023

How do you DIY sand floor turn into the blue and white color???